Manufacturing is one business sector that has been heavily affected by information technologies, and bigger changes are yet to come. However, the Global Digital Operations 2018 Survey by Strategy& found that 67% of global manufacturing companies show little or no enthusiasm for the idea of a digital transformation of their business. Read on to learn why manufacturers should not miss the opportunity to make the most of what digital transformation can provide them.

What Is Digital Transformation in the Manufacturing Industry?

As in other industries, manufacturing companies are struggling against strong market competition, and digital transformation has been helping them survive and thrive.

What is digital transformation in manufacturing?

Digital transformation in manufacturing is the adoption of digital solutions to replace legacy or non-digital manufacturing and near-manufacturing processes and operations in order to enhance business performance.

This smart, technology-driven manufacturing approach allows companies to make the most of industrial solutions and adapt production to changing conditions and requirements in real time, streamline processes, improve management and internal workflows, optimize production, or transform any other aspect of your manufacturing business.

This industry disposes of a great number of physical assets (from the factory floor, the supply chain, the back office, the IT infrastructure, etc.) and retrieves huge amounts of data (from CRM and ERP systems, transactions, social media, etc.). The goal of digital solutions here is to bring assets and data together in such a manner that they will combine to add value to every operation and process.

Industry 4.0 is the current industrial revolution that lies at the heart of digital transformation in manufacturing, as it automates processes and enables their real-time control. This is made possible through reliance on the efficient technologies that fuse together assets and data and combine digital with traditional factories to derive the best results.

Develop your custom software with SaM Solutions’ engineers, skilled in the latest tech and well-versed in multiple industries.

The Challenges

The introduction of advanced digital solutions helps businesses cut costs, enhance the customer experience and improve ROI; however, it has its challenges. What are the challenges that hinder digital transformation initiatives at manufacturing companies?

- The consent of upper management. Going digital inevitably involves heavy expenses and major workflow and HR management changes, which may be balked at by upper management.

- The realignment of the IT department. No technical transformation is possible without the proper tuning of all IT-related processes, the IT department structure and the technology stack.

- Personnel support. Changing processes, workflows, schedules and responsibilities, and employee retraining may be considered threatening or unwanted, and may be met with resistance by the personnel.

- Budget limitations. Technological innovations in manufacturing require a considerable budget, which may become an issue for many businesses.

- Extremely connected manufacturing systems. Systems where parts are tightly connected and delays are fatal may be unsuitable for changes and transformations.

- Changing customer behaviors. Customer demands have been constantly changing (from high service speed to higher product quality and to all-round customer experiences), requiring companies to second-guess future needs, which is why digital transformation initiatives should be thought out proactively.

- Turbulent geo-political and macro-economic conditions. Changing customer expectations, turbulent markets, disruptive competition, political uncertainty and other reasons make it difficult to create an all-encompassing transformation strategy.

The Benefits

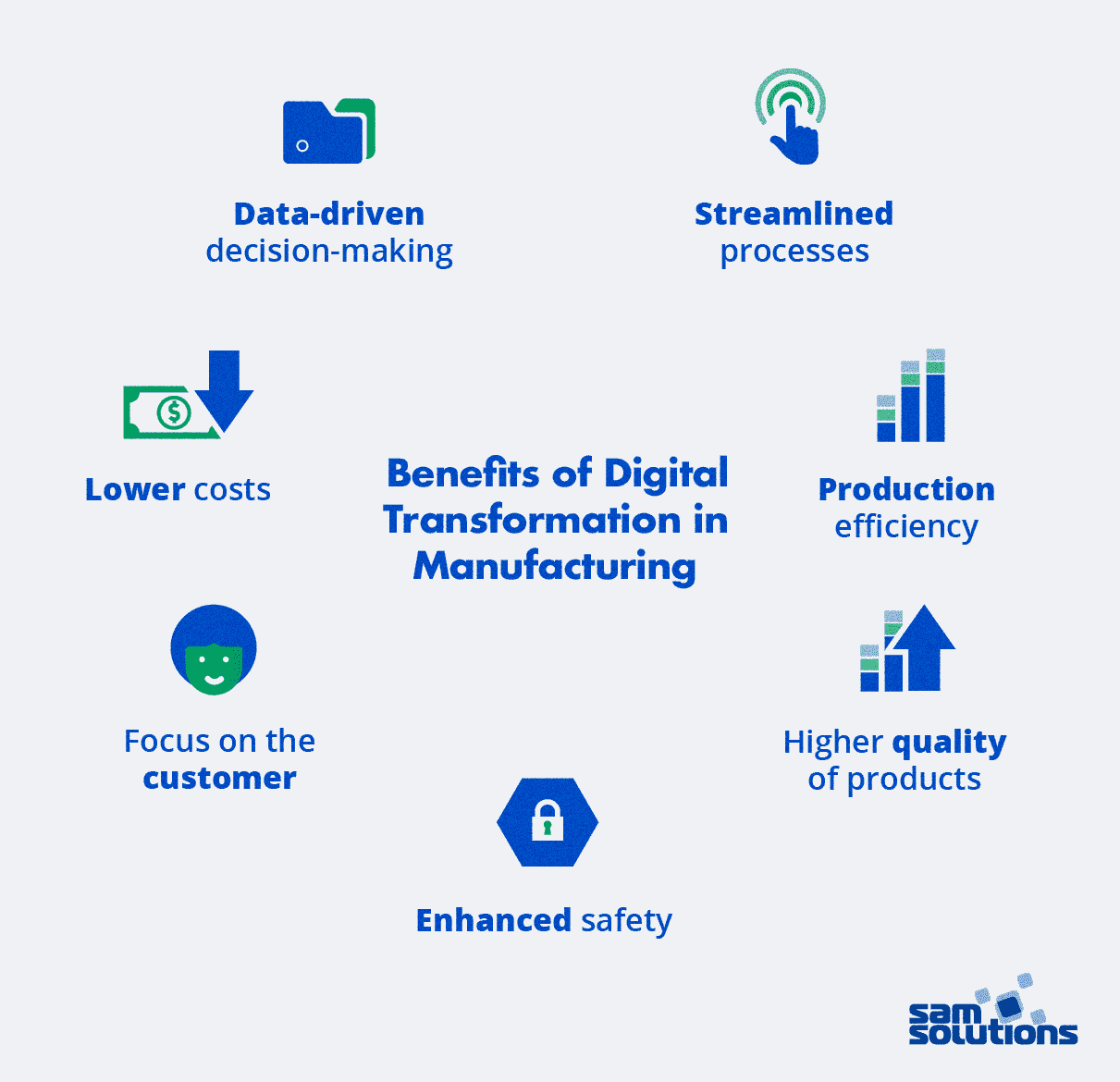

Supposing you decide to close the door on tried-and-true methods and tackle the above-mentioned challenges, what benefits does digital transformation provide to your manufacturing business?

- Data-driven decision-making. Manufacturers that have implemented a proper digital transformation strategy get to enjoy efficient data handling, processing, analytics and advanced decision-making, which is reflected in CRM, ERP, eCommerce and other systems.

- Streamlined processes. Many operations are automated and methods are revolutionized based on real-time insights, which helps optimize production and internal workflows.

- Production efficiency. Digital transformation is inextricably linked with technical innovations that improve process efficiency and use of the floor space.

- Better control. Real-time monitoring and advanced maintenance solutions enable an uninterrupted, 360-degree overview of the production processes and industrial capacities.

- Lower costs. Efficient workflows, process automation and optimized use of resources encourage labor savings and reduce expenses.

- Focus on the customer. Advanced software solutions allow manufacturers to synchronize production with customer needs by monitoring demand, ordering and their specifics according to a region, season, etc., as well as to shift from mass production to customized production.

- Higher quality of products. Enhanced processes enable better quality of assembly, bonding, blanking, etc., which is the key to enriched products.

- Enhanced safety. Digitalized processes help obviate human involvement in dangerous and difficult tasks, which contributes to safety and minimizes accidents.

Key Technologies

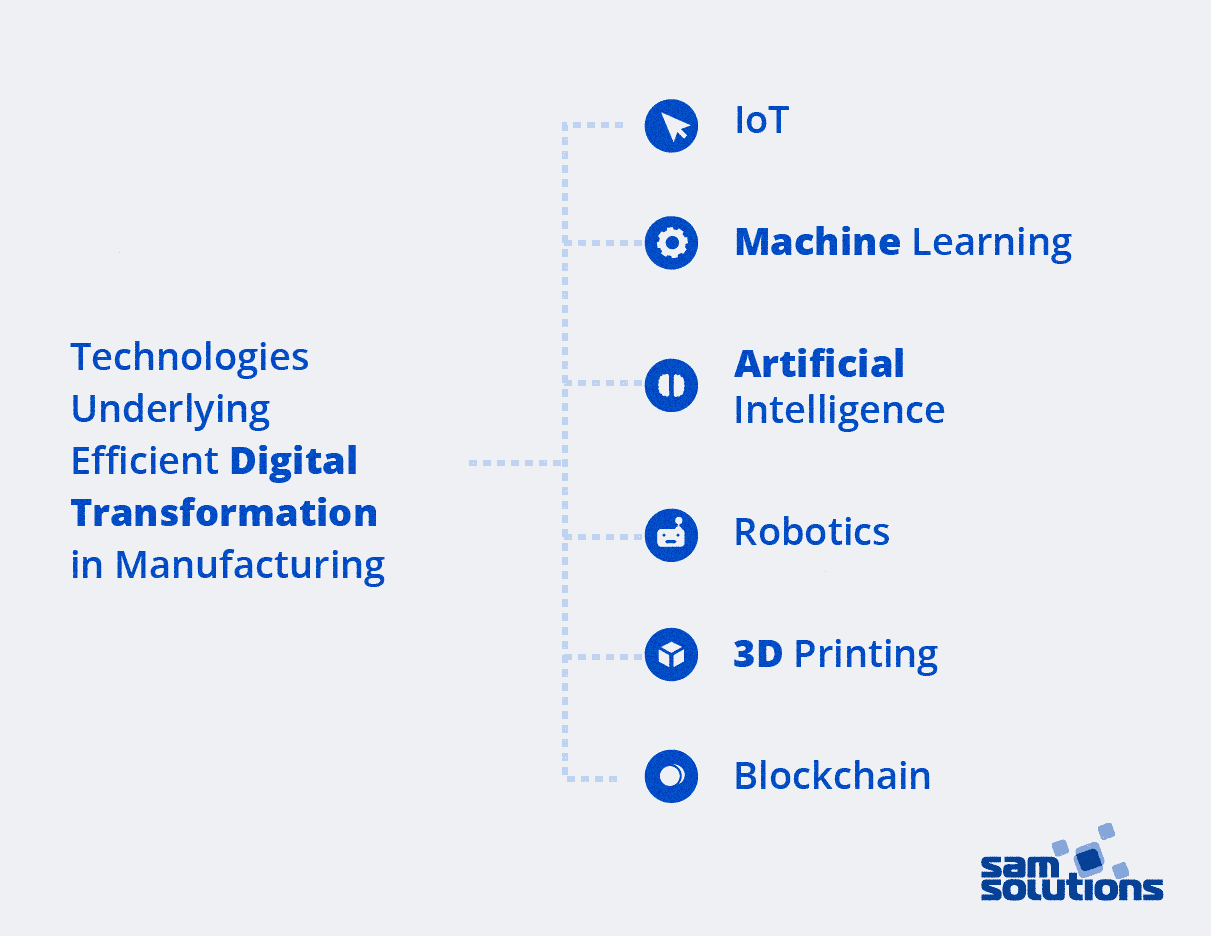

Let’s get to know the technologies that have been powering the most significant changes and improvements in the industry.

IoT

The Internet of Things, or the Industrial Internet of Things (IIoT), as it is frequently referred to in manufacturing, has become an integral part of almost all innovation in the industry.

By 2023, the manufacturing IoT market size is predicted to reach $994B, which is more than twice as much as in 2016, according to N-iX.

With IoT-based solutions, companies get a 360-degree overview of all their assets and facilities, enhancing their ability to monitor the production floor, enhance performance and address issues in real time.

These solutions significantly improve outcomes in such areas as production processes, personnel management and asset management. They do so by improving:

- production processes. IoT solutions streamline manufacturing operations, save energy and other resources, reduce errors, improve product quality, minimize downtime, etc.

- personnel management. IoT systems allow companies to monitor and boost their employees’ productivity, as well as to build a comfortable working environment for them.

- asset management. IoT solutions have access to and overview of all connected devices, which is why they can easily monitor inventory, track performance, ensure maintenance, etc.

Machine Learning

Smart algorithms that mimic the human ability to learn are the key to machine learning solutions and, thus, to many efficient systems that help manufacturers improve their operations. Changing the way businesses collect data and make predictions, smart algorithms also prevent the loss of quality to effectiveness by finding the perfect balance between the two.

Another important capability of machine learning solutions is their higher effectiveness in comparison to humans, which reduces waste and errors, and improves accuracy and precision.

Some good examples of how machine learning algorithms can be used in the industry are prediction of customer demand, shipping times, delays, models of risk prevention, etc.

Artificial Intelligence

Artificial intelligence systems are very much different from traditional pre-programmed systems and provide completely different benefits and capabilities to manufacturing companies. It’s not people who train and program machines; it’s rather AI solutions that analyze data, teach themselves, discover patterns and deliver immeasurable insights to people.

The capability of AI-based systems to perceive information and think like people is great for a variety of manufacturing tasks, such as:

- decision-making

- product and feature configuration

- quality control and issue detection

- predictive maintenance

- predictive analytics.

Robotics

“Pandemic will jumpstart automated manufacturing,” says Michael Tyrrell, Digital Coordinator at the International Federation of Robotics.

To make the most of the capabilities of industrial robots for business, companies should ensure their smooth and efficient introduction.

Collaborative and easily trainable robots can help manufacturers by:

- automating assembly lines

- automating tedious, repetitive operations

- controlling complex processes

- monitoring performance

- collecting data

- making data-driven decisions

- replacing humans for dangerous and difficult tasks.

Although requiring considerable initial investments and ongoing costs, the implementation of robotics in industrial operations increases productiveness and speed, improves product quality, minimizes downtime and enhances safety.

Real-life example. A fruit supplier Linden cut labor costs and increased production by 50% with an automated assembly line.

3D Printing

Despite being quite a young technology, 3D printing has already helped many manufacturers accelerate their production cycles. How? This additive technology helps make prototypes and quickly and easily produce component parts that would otherwise be shipped with a time lag. An added benefit is that in addition to its speed, it’s also cheap.

The process is that a manufacturer creates a design, while a 3D printer creates it out of resin, plastic and/or other materials. The technology allows manufacturers to cut costs and reduce time to market.

Blockchain

Created for Bitcoin, this technology has quickly been adopted by several other domains, including the manufacturing industry. In manufacturing, it helps design smart supply chains that can track every moment and aspect of the product’s lifecycle.

Because of this transparency, operations are protected against fraud, theft, cyber attacks, etc. If working in collaboration with IoT, the IoT system doesn’t have to handle devices through the central cloud server.

Current Trends

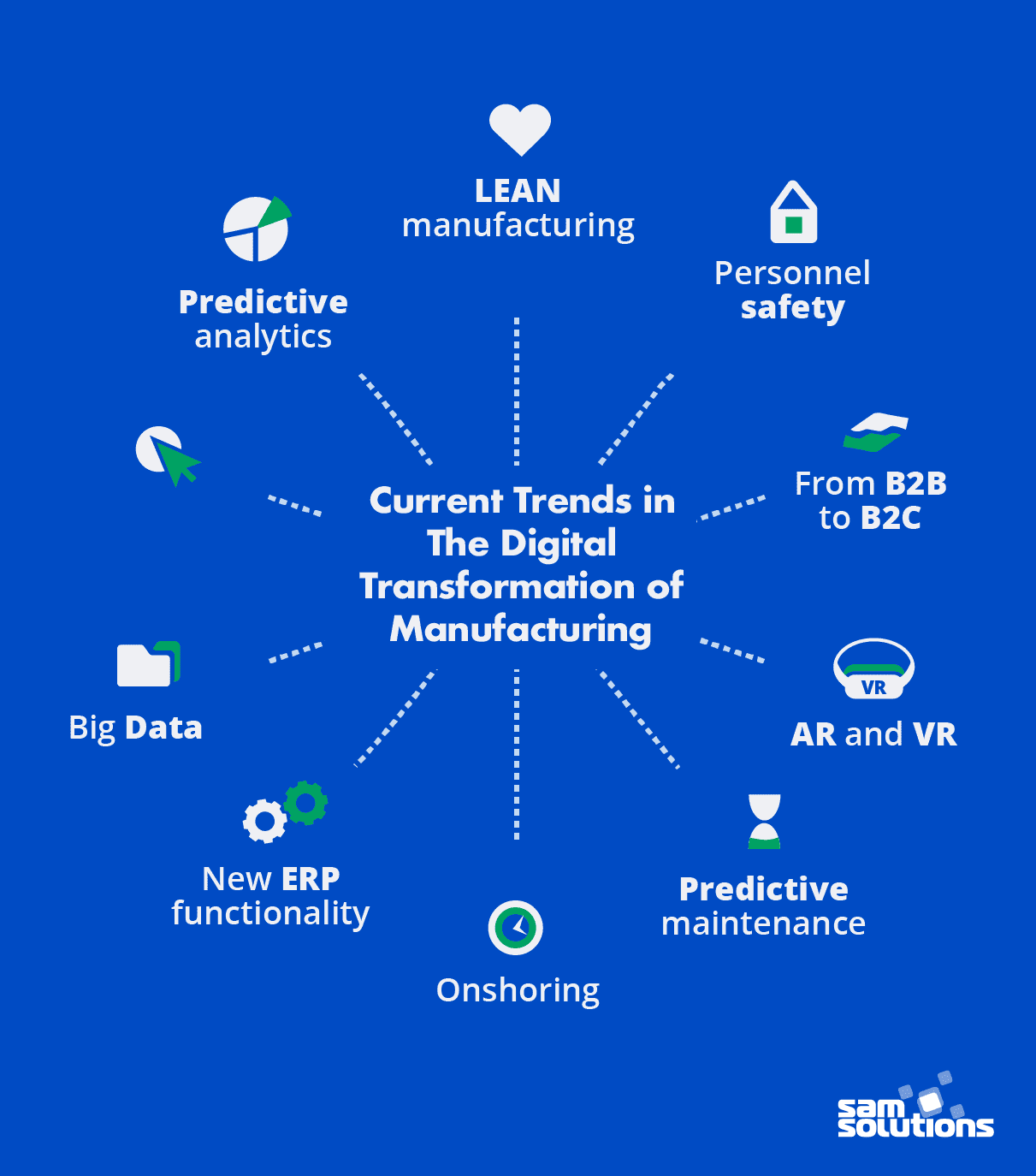

Technologies, methods and approaches change at the speed of light, throwing entire industries into turmoil, to which manufacturing is no exception. Let’s explore the current trends that impact the digital transformation in the industry.

Predictive Analysis as the Basis of Decision-Making

At a certain stage of a manufacturer’s maturity, predictive analytics gathers huge amounts of data that can provide valuable insights if properly processed. Predictive analytics solutions combine machine learning algorithms, big data processing tools and cloud computing technologies to help companies interpret data such as:

- personnel productiveness

- customer demand

- production effectiveness

- lead and shipping time

- cost efficiency

- safety issues.

These solutions not only analyze the current situation but also help find areas for improvement, such as ROI maximization, process streamlining, inventory management optimization and the improvement of operational efficiency.

LEAN Manufacturing to Ensure Eco-Friendliness and Effectiveness

Being eco-friendly is a matter of concern for many manufacturers, and LEAN manufacturing is a way to minimize waste while ensuring high productivity. The LEAN approach relies heavily on predictive analytics that encourages data-driven decision-making. Following this approach, a company optimizes all operations and reduces waste at the same time.

By doing so, this industrial approach helps ensure that:

- all defects are detected and fixed

- production is aligned with demand

- employee time and production facilities are used in the most efficient manner

- logistics is well-thought-out.

As you can see, LEAN manufacturing is all about the rational use of all resources. It ensures increased quality of products, ease of management, safety and process efficiency.

Safety as the Major Priority

Employee safety has become increasingly important, especially with the recent pandemic. For this reason, businesses have made maximum use of digital solutions not only to replace humans with machines on dangerous tasks, but also to ensure distancing and minimize close physical contact.

IoT Is Gaining Traction

The Internet of Things is not new to the industry, but its use is growing in intensity. The reason is probably that IoT makes life easier for manufacturers, as efficient asset management is impossible without sound IoT networks.

Statistics prove the rising popularity of IoT: spending on the technology will reach $1.1 trillion by 2023, and the number of device connections worldwide will amount to 21.5 billion by 2025, according to Statista.

The manufacturing industry will certainly become one of the core consumers of the Internet of Things. This is especially important during the pandemic, as IoT enables powerful remote monitoring solutions.

Predictive Maintenance Wins Hearts

There is a growing demand for predictive maintenance across manufacturing businesses as it helps prevent loss of efficiency, stoppage and significant costs (the cost of one-hour downtime is more than $100,000, according to an ITIC survey). Such solutions analyze equipment within networks and detect future outages so that factories can align their maintenance schedules and perform maintenance proactively.

Real-life example. By relying on a predictive maintenance system, Tetra Pak, a packaging producer, ensures high quality and uninterrupted production of its packaging.

With predictive maintenance solutions, manufacturers understand how their systems work, predict their behavior and control them completely, while saving money, time and resources.

Transition from B2B to B2C

Manufacturers have started to shift from impersonalized sales to customer-centricity — unmediated transactions with their ultimate clients have become one of the priorities. And for good reason — by leaving out intermediaries, this business model provides both parties with the following benefits:

- Financial. Companies get the full profit based on the manufacturer’s recommended retail price, while customers can buy at prices that don’t include the intermediaries’ commission.

- Time-related. Companies release products faster, and customers get products faster.

- Reputational. Companies are in complete control of their brand reputation, and buyers aren’t disoriented by possible poor representation by intermediaries.

- Quality-related. Because it’s now possible to track clients’ response and behavior firsthand, manufacturers can quickly make the necessary changes to produce products of higher quality and provide a better customer experience.

To enable efficient sales, manufacturers need powerful eCommerce platforms that support both B2C and B2B and allow companies to manage orders, make transactions, perform marketing activities and have a complete overview of all customer interactions. Easy synching with other internal systems, such as ERP and others, is a must-have functionality for modern eCommerce platforms.

Real-life example. A comprehensive platform that brings together B2B and B2C sales helps the US-based salt company SaltWorks improve customer experience and boost sales.

The Reinforcement of ERP Solutions

Enterprise resource planning (ERP) solutions have always been important in manufacturing, as they automate many hefty and data-intensive tasks and provide real-time, precise information. Recently, companies have started to enrich these solutions with additional layers of applications that perform tangent functions that are urgently needed in the industry.

Working as a complement to the existing software, this approach doesn’t require significant changes to ERP systems and enables quick and easy time to value.

Greater Focus on Big Data

The high popularity of predictive maintenance and IoT solutions and the increasing number of connected devices and sensors that collect data necessitates proper management of unstructured data, which puts big data processing in focus.

AR and VR to Replace Humans for Some Tasks

With IoT, human contact has been minimized in many areas of life, and manufacturing is no exception. The capabilities of AR and VR allow companies to use them for a wide variety of cases, such as remote troubleshooting, testing, training, etc.

Back to Onshoring

Many manufacturers have been returning to onshore, domestic production instead of offshoring.

According to Supply Chain Management Review, almost 750,000 jobs were brought back to the US between 2010 and 2018.

Companies do so because of the following advantages that reshoring provides to them:

- Strengthening of economies in go-to countries that leads to an increase in labor costs, and other expenses

- Lack of required infrastructure in countries with cheap labor

- Growing transport costs

- Advanced technologies and tools replacing human employees

Naturally, the pandemic is also an aspect to take into account, as it has forced many producers to reduce dependency on foreign suppliers and partners.

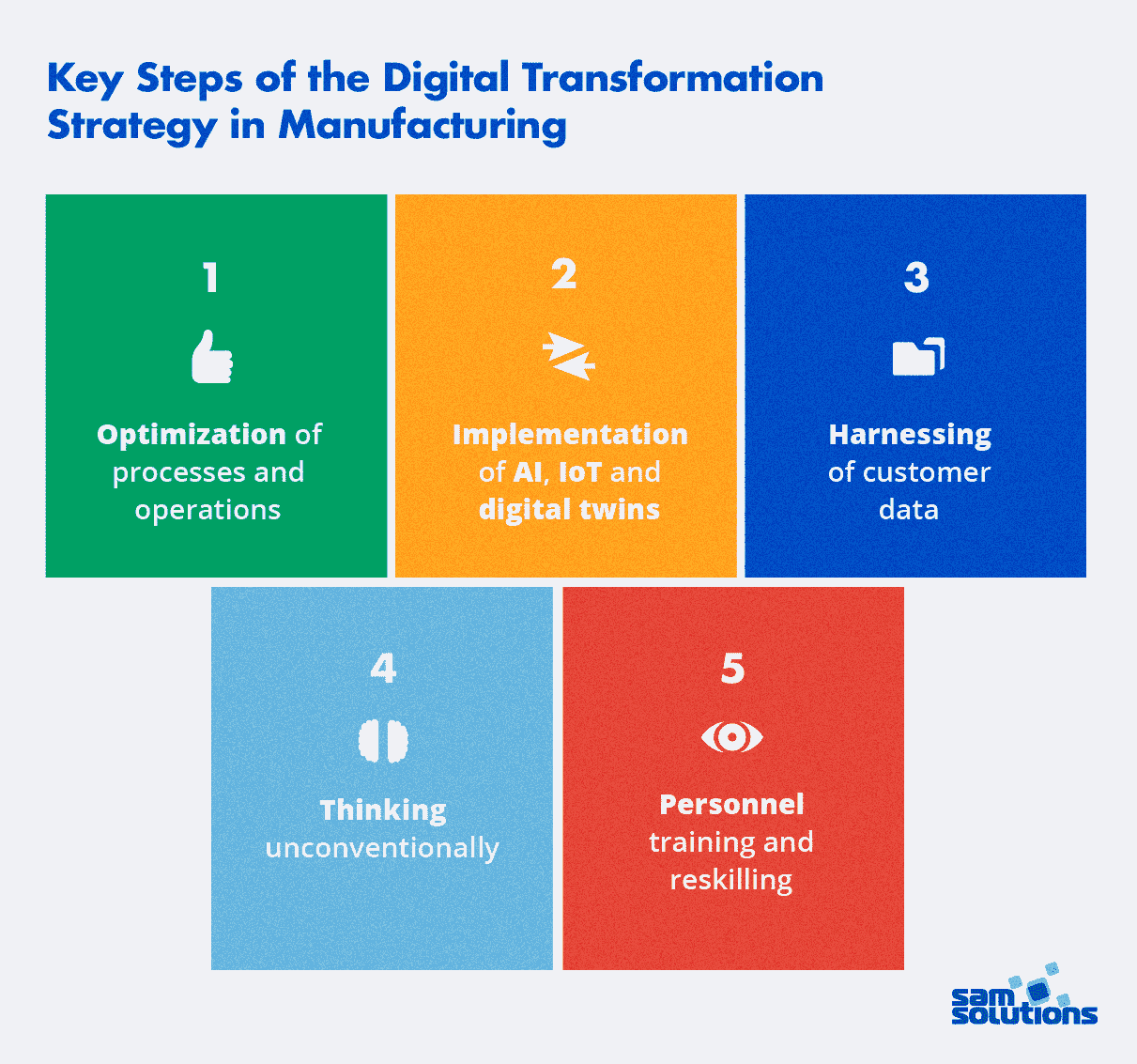

A Transformation Strategy

Transition from conventional manufacturing procedures is a costly, complex and long process (but one definitely worth the hardship). To make it as smooth as possible, a company needs a circumspect strategy. Let’s find out what basic steps a good strategy should include.

Optimization of Processes and Operations

Companies should assess their IT capabilities, do a cost-benefit analysis and identify areas of improvement in every aspect of their business, such as production, HR, product quality assurance, etc. LEAN manufacturing serves well here as it helps find these areas and elaborate a change strategy.

Together with engineering, operational and information technology, process optimization will encourage new, more efficient working models and enhancement roadmaps.

Implementation of AI and IoT

These technologies are impressively efficient in the manufacturing industry, as they help boost productivity, raise profits and minimize waste. To enjoy all these benefits, companies should prioritize their introduction and seamless integration with engineering and operational technologies.

Harnessing Customer Data

Modern direct-to-customer business models allow manufacturers to understand their clients and their requirements by gathering and processing their information. By building a system that can store and manipulate customer information, manufacturing companies can get closer to their end customers and better meet their needs, and therefore demand.

Thinking Unconventionally

To win over customers, some manufacturers think outside the box. One such manufacturer is John Deere: this tractor producer built an online store selling a wide range of complement and related products. This innovative approach allows the company to gather client data and drive revenue in an unconventional way that has put it squarely ahead of the competition.

Personnel Training and Reskilling

Complex devices and sophisticated platforms require completely new skills and knowledge, which is why companies should invest in employee training or hiring new team members. This means that they should prepare for considerable costs and time investment.

Digital Transformation as a Multifaceted Approach

A manufacturer on a digital transformation journey should see it as a complex approach that exceeds the limits of the transformation of the manufacturing floor. It’s the transformation of every aspect of the production and supply chain that enables the most efficient changes to the entire business.

To learn more about improvements that you can make or elaborate a full-fledged digital transformation strategy, contact our experts.

The Latest 15 Information Technology Trends in 2024

The Latest 15 Information Technology Trends in 2024 Top 10 Embedded Software Development Tools

Top 10 Embedded Software Development Tools IaaS vs. PaaS vs. SaaS: What’s the Difference?

IaaS vs. PaaS vs. SaaS: What’s the Difference? 10 Examples of Predictive Analytics

10 Examples of Predictive Analytics

![Digital Transformation Strategy [+ Key Trends in 2024]](https://www.sam-solutions.com/blog/wp-content/uploads/2020/07/main-Digital-Transformation-Strategy-min.png)

Web App Development Cost in 2025 [Key Price Factors]

Web App Development Cost in 2025 [Key Price Factors] 13 Best React Development Tools in 2025

13 Best React Development Tools in 2025 Top 10 Mobile App Development Trends 2025

Top 10 Mobile App Development Trends 2025 Top IoT Industry Trends in 2025

Top IoT Industry Trends in 2025 Java Web App Security: Everything You Need to Know

Java Web App Security: Everything You Need to Know

This change in the activities of a company is now widely referred to as digital transformation. … Digital Transformation fundamentally changes how companies create, monetize and defend value, giving companies the much-needed competitive edge.

Thank you for this article! I was doing research for this topic, and your article was really useful!

I hope that digital transformation in manufacturing will help us reduce the carbon footprint and encourage safer and more sustainable production processes.

Wow! I had no idea that some manufacturers already used all these approaches and technologies. I’m sure it has helped them improve their processes.

It’s amazing how much a company will achieve if it efficiently implements all these technologies. I think that today businesses are still resisting to introduce cutting-edge technologies and innovations because of severe conservatism and a fear of initial expenses.

I cannot but agree that digital transformation has completely recreated the environment in which manufacturing exists. It has encouraged more efficient processes, more employee productivity and endless innovations

Indeed, digital transformation is making crucial changes to processes and operations, and manufacturing is no exception. In my opinion, information technologies only improve the industry and make it eco-friendlier and more productive.